Stepper Driver | Servo Driver

DMX512 Stepper Driver | DMX512 Servo Driver | DMX512 Motion Controller | Integrates DMX512 Protocol | DMX512 Stepper Motor | DMX512 Servo Motor

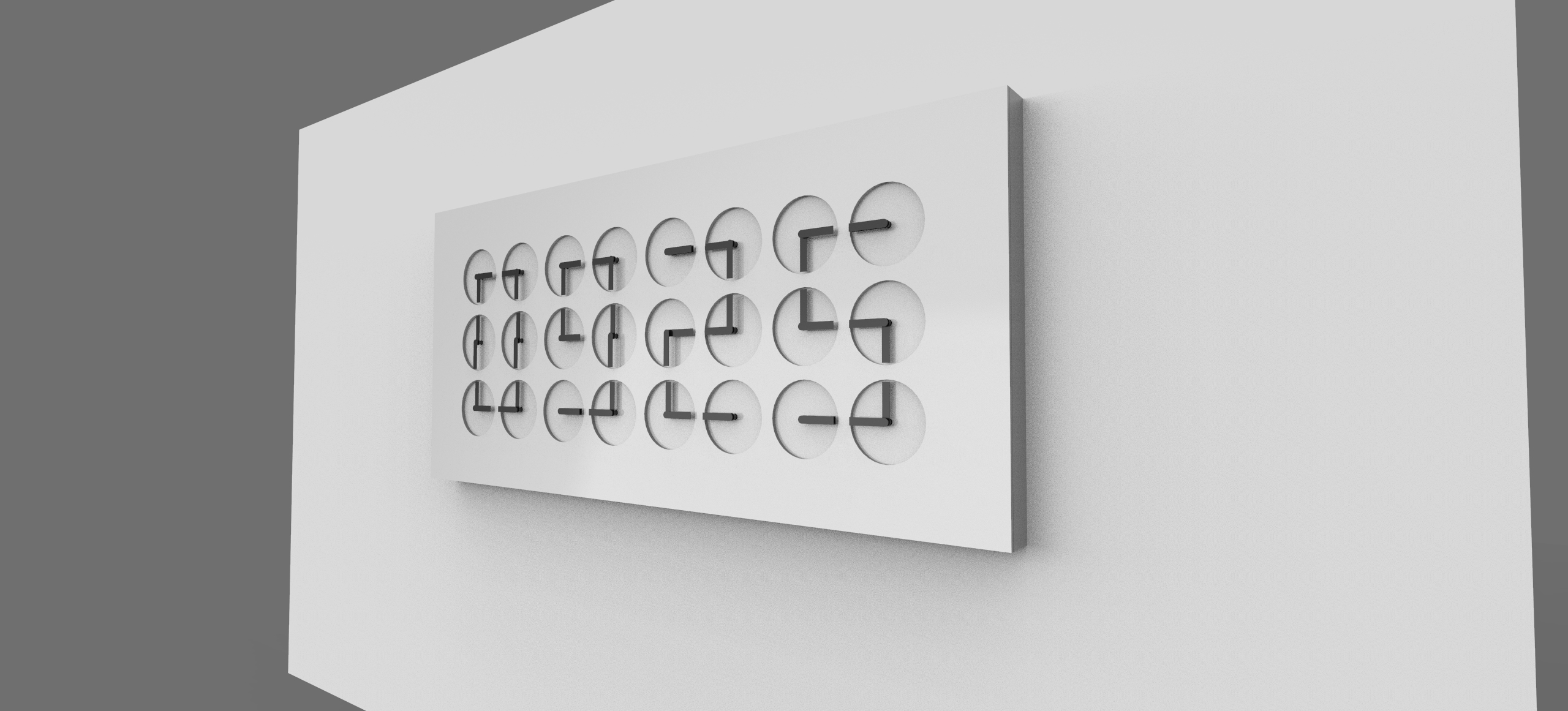

Stage Machinery.Architectural Lighting.Smart Home.Advertising Signs.Exhibition and Display. Mechanical Dynamic Matrix

What Can It Do?

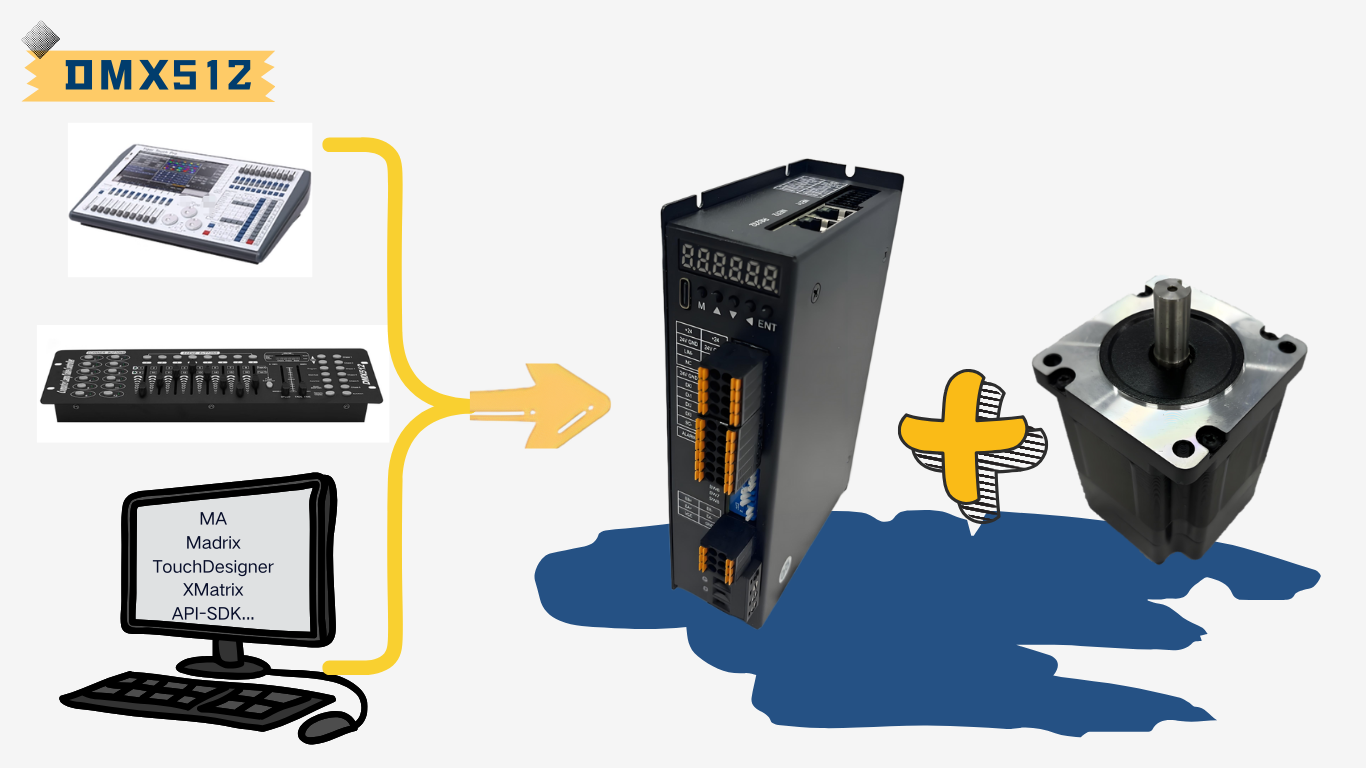

By using the DMX512 protocol interface, you can complete motor movement, programming, and interaction, perform flexible actions, automate tedious tasks, build complex workflows, and improve your efficiency to a whole new level. Let you forget the trivial details of motor parameters, driver parameters, and motion controllers.

Fast Startup

- Set Home mode (sensor reset, absolute value reset, trip home)

- Set the direction of the motor

- Set the maximum speed of the motor

- Set the maximum stroke of the motor

- Set the DMX channel control mode:

Single channel P mode: DMX channel 1, controls motor position. For example, 0-255 of DMX512 corresponds to different positions of the motor

Dual channel PV mode: DMX channel 1 controls motor position, channel 2 is motor movement speed

Three channel PPV mode: DMX channel 1+channel 2 combination for motor position, channel 3 for motor speed. Achieve higher precision position control - Compatible with market standard lighting control consoles, Madrix, MA, Touch Designer, XMatrix and other main control systems. Quickly complete project evaluation

Lets Begin

Based on the DMX512 protocol Stepper Driver ,Servo Driver , we provide a powerful, flexible, and reliable stepper motor drive control solution for the industry.Addressing the pain points of traditional stepper motors and servo motors, such as poor console compatibility, fixed functionality, complex wiring, need for external controllers, and complex debugging.

The driver support DMX512, reducing the threshold for wiring and debugging. No external controller required, no need to consider compatibility with different brands of drivers

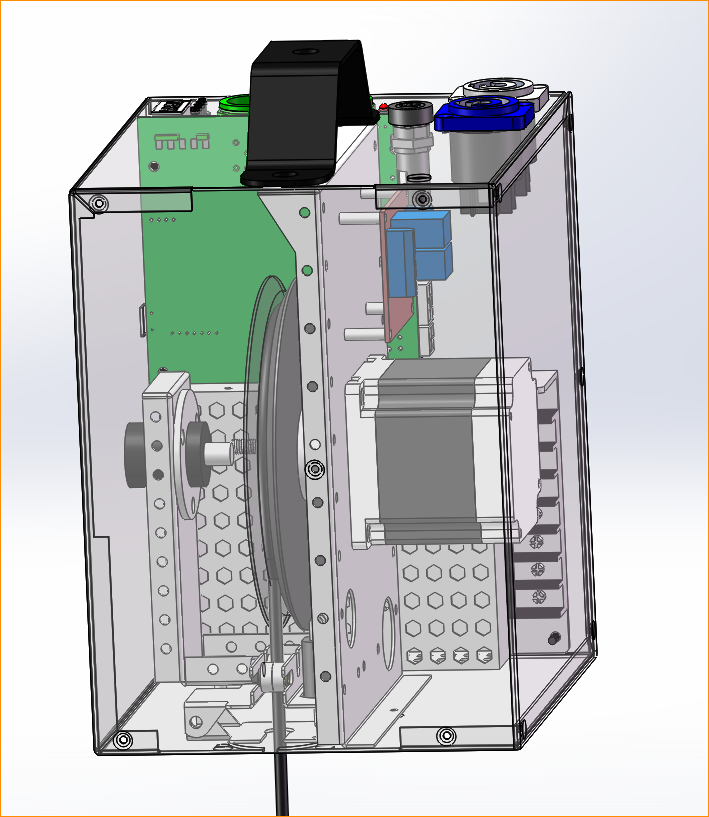

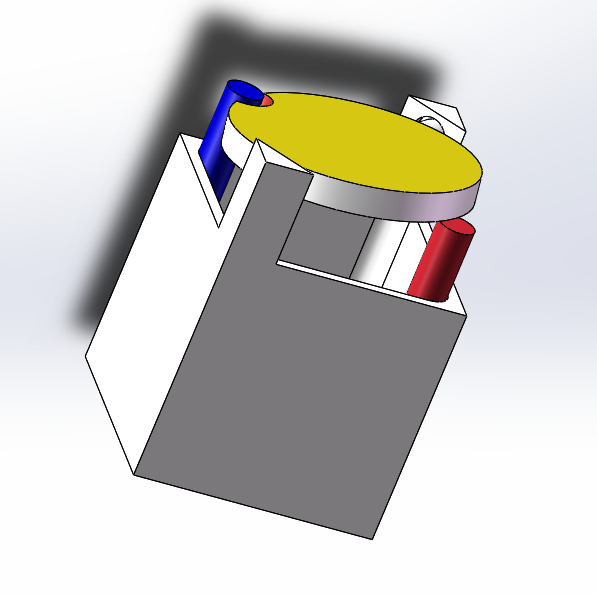

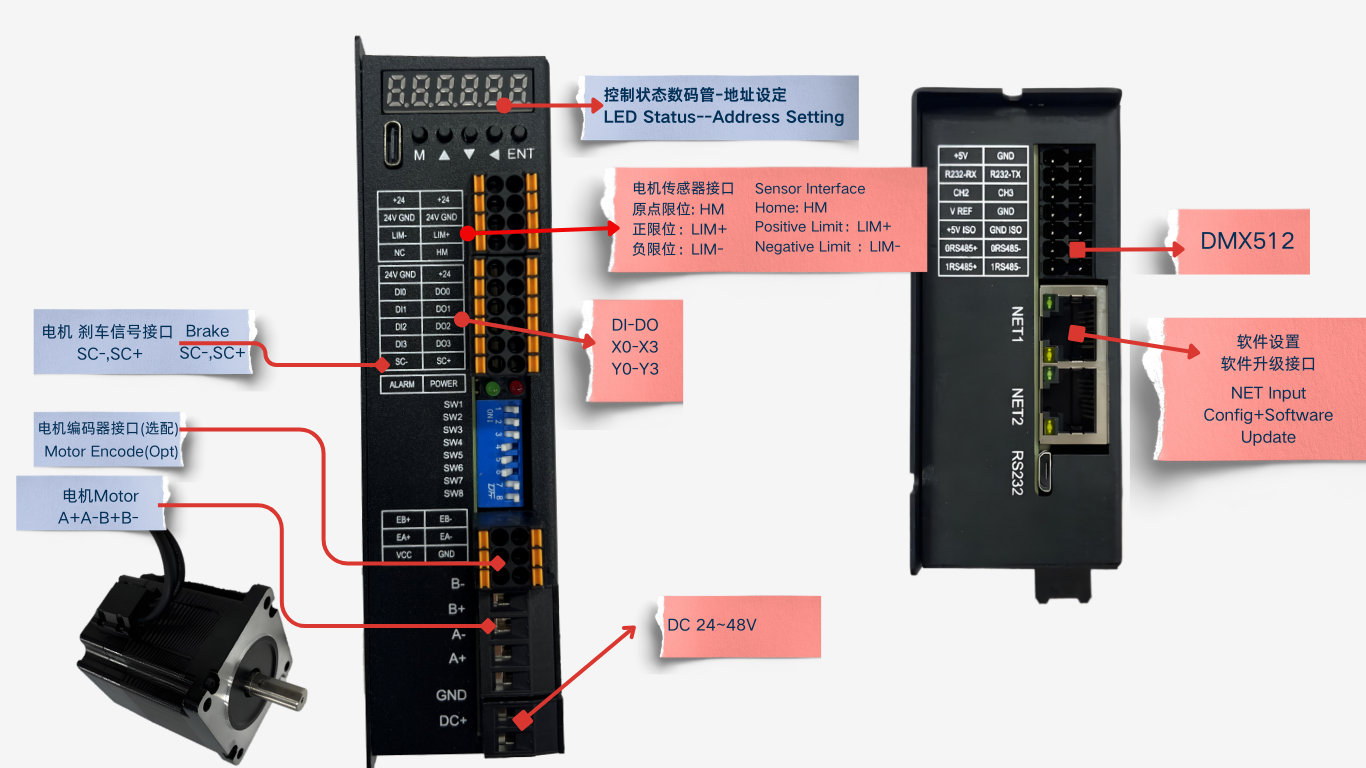

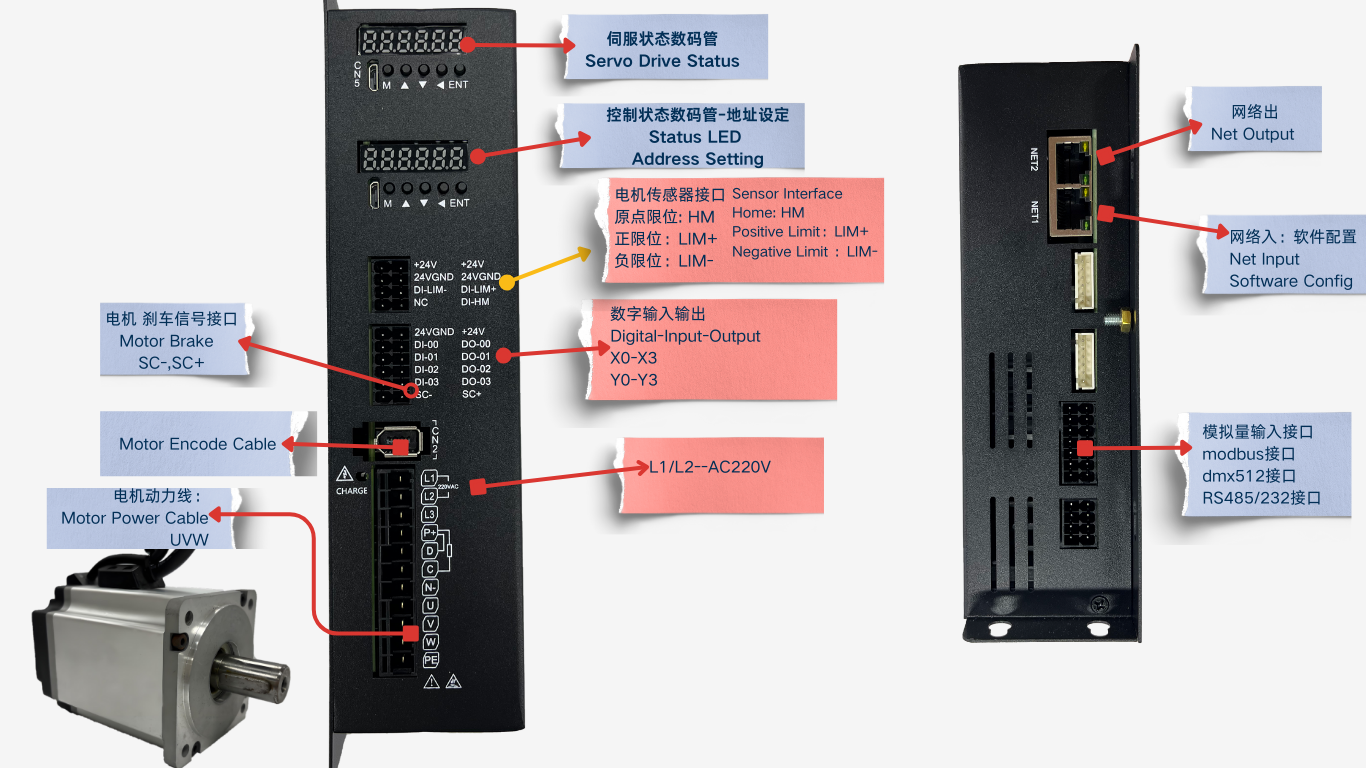

Hardware Carrier

Function Points

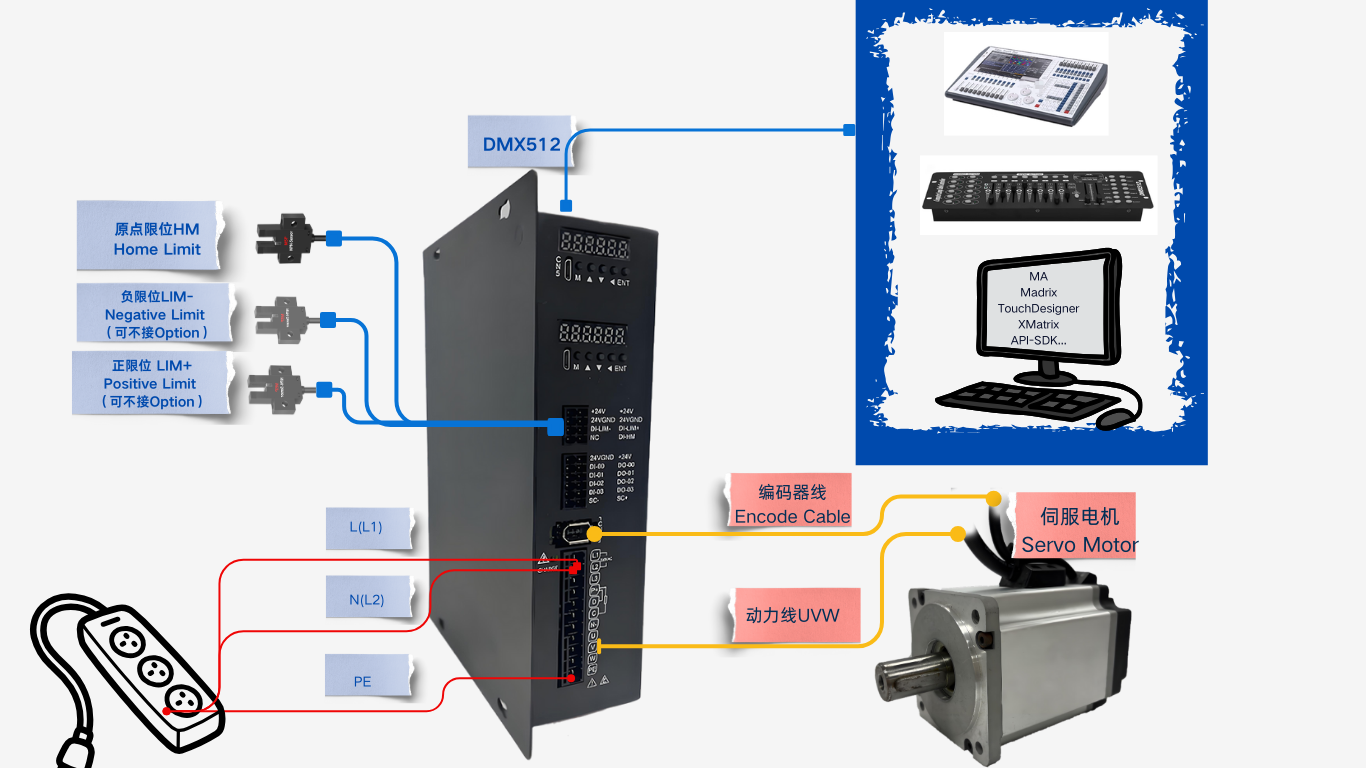

Application Diagram

Product

Perfectly combining industrial grade motion control accuracy with the DMX512 protocol, allowing familiar consoles, Madrix, Touch Designer, and others to directly and accurately command motors to complete complex motion sequences.

Seamless support for XMatrix dedicated mechanical control software.

Value

Function

- Excellent motion control performance

- Integrated motion control algorithm, supporting S/T acceleration and deceleration. Support emergency stop and deceleration stop. Supports symmetric acceleration and deceleration, as well as asymmetric acceleration and deceleration curves.

- Absolute position movement, relative position movement, Jog velocity movement, supports associative movement.

- Home limit, positive limit, negative limit, ensure mechanical protection.

- Software limit protection, event triggered stop protection, maximum speed limit.

- Support Multiple HOME Mode(reset)

- Photoelectric Sensor returns to HOME

- Absolute Encoder returns to HOME (Servo System)

- Torque return to HOME

- Skip HOME

- Customized Home

- User value: Adopt appropriate zeroing modes for different mechanical structures

- Wide Compatibility and Flexibility

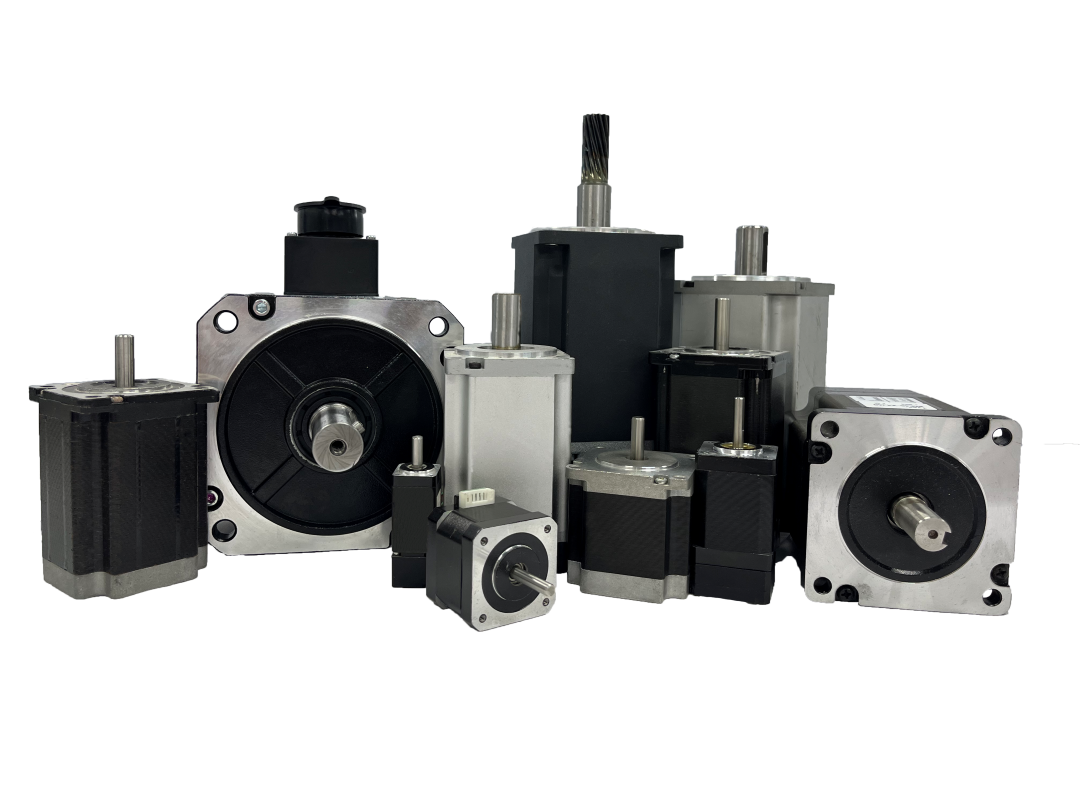

- Stepper Controller ST-Series Supports a wide range of power supply voltages (24V-48V DC) and can be adapted to various sizes of 42, 57, 60, 86 stepper motors from NEMA17 to NEMA34, providing you with great project design flexibility. Covering small and medium power scenarios

- Servo Controller SV-Series: Powered by AC220V and AC110V, it can adapt to 100W, 200W, 400W, 750W, 1000W, and 1500W servo motors, providing you with great project design flexibility. Covering small and medium power scenarios

- Motion Controller MC-Series, supporting third-party drivers, motors, stepping, servo, and any power specification

- Advanced Software and Maintainability

- Support Online Upgrade, firmware upgrade can be easily completed through network interface. Get the latest features and performance optimizations without disassembling the equipment, worry free for the future.

- Powerful Software DIY function

- We provide user-friendly PC configuration software that allows users to deeply customize motor parameters (such as micro step resolution, current, acceleration curve), zeroing mode, DMX channel allocation, mode mapping, etc.

- Advanced users can perform secondary development through the provided protocol interface to achieve fully customized control logic.

- DMX512 Protocol Fully Compatible

- Fully supports DMX512 protocol

- Native support for DMX512 protocol, compatible with mainstream lighting consoles such as MA and Madrix, supports Art Net protocol, supports XMatrix, Touch Designer without changing existing workflows.

- Supporting the Art Net protocol, it can be easily integrated into large distributed networks through Ethernet, enabling centralized control of up to tens of thousands of channels.

- DMX512-Multiple channel control modes (P, PV, PPV)

- P (Position Mode): Directly specify the target position of the motor through the DMX value (0-255 corresponds to 0-360 ° or custom stroke)

- PV (Position+Speed Mode): The position is controlled by a separate channel, while the operating speed is controlled by another channel

- PPV (Position+Position+Velocity Mode): Multi channel collaboration enables more complex high-precision control of position and velocity curves.

- DIY mode: accepting software customization and development, customizing channel functions to better meet your process needs

- User value: Comprehensive control from simple movement to complex curve motion can be achieved solely through DMX values

Interface

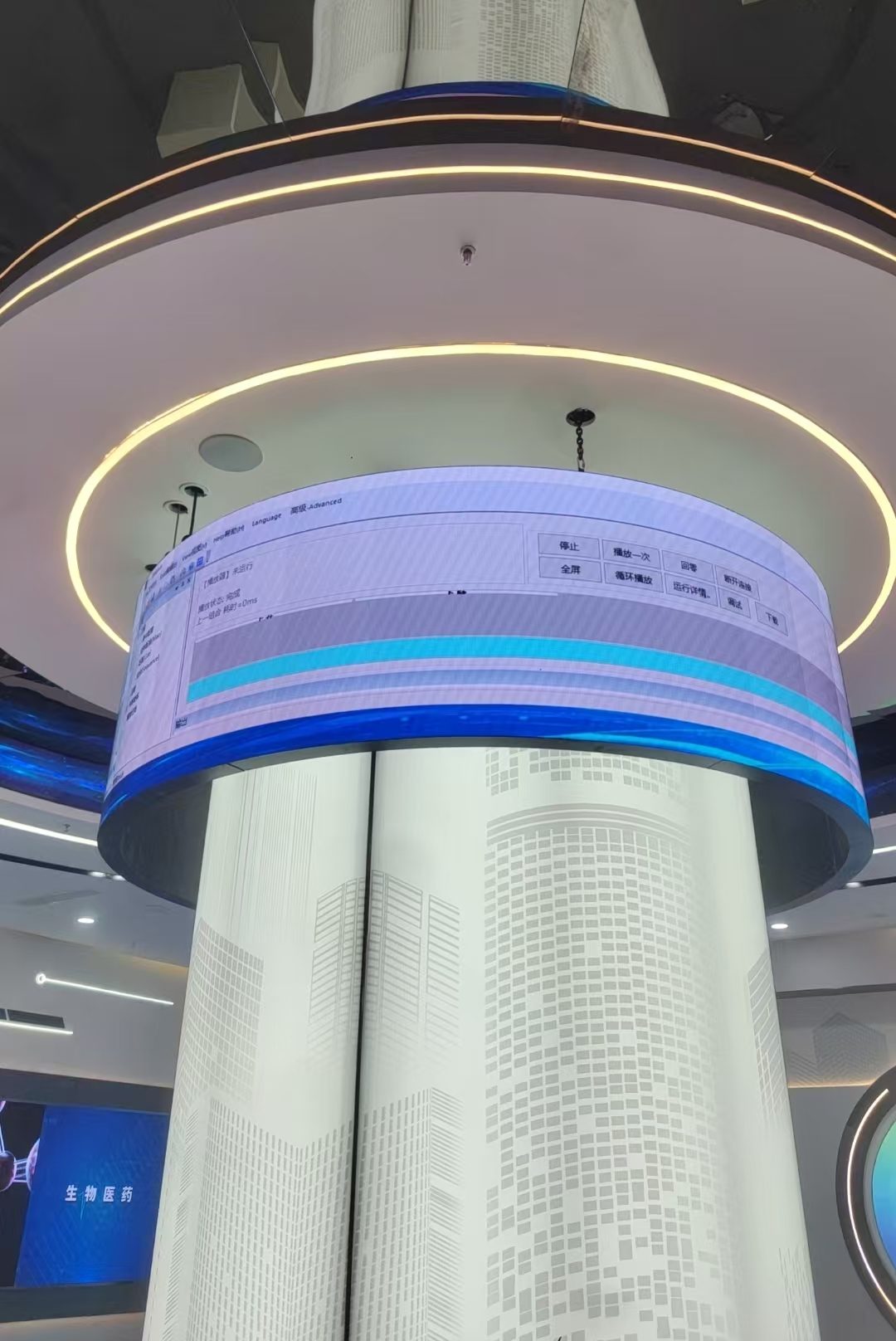

Application

Stage machinery: control the movement of moving head lights, special effects devices, and robotic arms

Architectural lighting: driving dynamic facades and movable decorative components

Art installation: providing precise power for interactive art and dynamic sculpture

Exhibition Display: Advertising Signs, Screen Machinery

Non standard Machinery: Non standard Machinery&General Control

Minimum System

Specifications

Control Protocol: DMX512

Motor Type: stepper motor, servo motor

Control Modes: P, PV, PPV, software customization mode

Communication Interface: DMX IN/OUT, Ethernet (for configuration/Upgrade)

Protection Function: overcurrent, overvoltage, undervoltage, short circuit protection

Working Temperature: 0~70 ° C

Cooling Method: natural cooling or forced cold air

Usage: Try to avoid dust, oil mist, and corrosive gases as much as possible

Storage temperature: -20 ° C~80 ° C

Technology

Other Information

| Number | Motor | Open | Close | Max-RPM | Torque-NM | AbsoluteEncode | Brake | In-Out | Ethernet/udp/tcp/raw | DMX512/485 | FirmwareUpdate |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MGSI-Serise Mechanical Dynamic Matrix | Stepper | ||||||||||

| MGSI42 | 42 | √ | – | 300 | 0.5 | – | – | – | – | √ | – |

| MGSI43 | 42 | √ | √ | 300 | 0.5 | – | – | – | – | √ | – |

| MGSI57 | 57 | √ | – | 300 | 2 | – | – | 4+4 | – | √ | – |

| ST-Series | Stepper | ||||||||||

| MSP-DMX-ST-42 | 42 | √ | √ | 300~1000 | 0.5 | – | √ | 4+4 | √ | √ | √ |

| MSP-DMX-ST-57 | 57 | √ | √ | 300~1000 | 2 | – | √ | 4+4 | √ | √ | √ |

| MSP-DMX-ST-60 | 60 | √ | √ | 300~1000 | 3 | – | √ | 4+4 | √ | √ | √ |

| MSP-DMX-ST-86 | 86 | √ | √ | 300~1000 | 8.5 | – | √ | 4+4 | √ | √ | √ |

| SV-Series | Servo | ||||||||||

| MSP-DMX-SV-100 | 100W | – | √ | 3000 | 0.32 | ||||||

| MSP-DMX-SV-200 | 200W | – | √ | 3000 | 0.64 | √ | √ | 4+4 | √ | √ | √ |

| MSP-DMX-SV-400 | 400W | – | √ | 3000 | 1.27 | √ | √ | 4+4 | √ | √ | √ |

| MSP-DMX-SV-750 | 750W | – | √ | 3000 | 2.39 | √ | √ | 4+4 | √ | √ | √ |

| MSP-DMX-SV-1000 | 1000W | – | √ | 3000 | 3.18 | √ | √ | 4+4 | √ | √ | √ |

| MSP-DMX-SV-1500 | 1500W | – | √ | 3000 | 4.77 | √ | √ | 4+4 | √ | √ | √ |

| MC-Series | Single Axis Controller | ||||||||||

| MSP-DMX-MC-1001 | External Drive | – | – | – | – | * | * | 4+4 | √ | √ | √ |

*Confirmation is required for value-added selection

| Parameter | MGSI | ST | SV | MC |

|---|---|---|---|---|

| Motor Dir | √ | √ | √ | √ |

| Max-Position | √ | √ | √ | √ |

| Home Speed | √ | √ | √ | √ |

| Home Offset | √ | √ | √ | √ |

| Acc and Dec Curve | S | S/T | S/T | S/T |

| Asymmetric ACC and DEC | – | √ | √ | √ |

| Maximum speed limit | √ | √ | √ | √ |

| Home Method | Limit Home | Limit Home Skip Home | Limit Home Skip Home Troque Home Absolute Home | Limit Home Skip Home Troque Home Absolute Home |

| Torque limit | – | – | √ | * |

| Error Handle | Shutdown; Restart; Reset; | Shutdown; Restart; Reset; | Shutdown; Restart; Reset; | Shutdown; Restart; Reset; |

| Positive and Negative limit alarm | √ | √ | √ | √ |

| Support External Drives | √ | – | – | √ |

| Software changes current | √ | √ | – | – |

| IO Filter | – | √ | √ | √ |

| Emergency Stop | – | IMD/DEC Stop | IMD/DEC Stop | IMD/DEC Stop |

| Sequence Home | – | √ | √ | √ |

| Delay before positive negative move | – | √ | √ | √ |

| Absolute Encoder | – | – | √ | * |

| Modbus Master | – | * | * | * |

| Mode | PV,PPV | P,PV,PPV | P,PV,PPV | P,PV,PPV |

| Online Upgrade | – | √ | √ | √ |

*is Option

Application Cases