DMX512 | UDP Command| No-Programming| API-SDK| Script| PLC Ladder| Stepper Motor| Servo Motor| Stepper Drive Controller| Servo Drive Controller| Motion Controller

Drive-Controller Interface

Technical Support

Professional Engineers and Provide Free Project Support

What Can We Do?

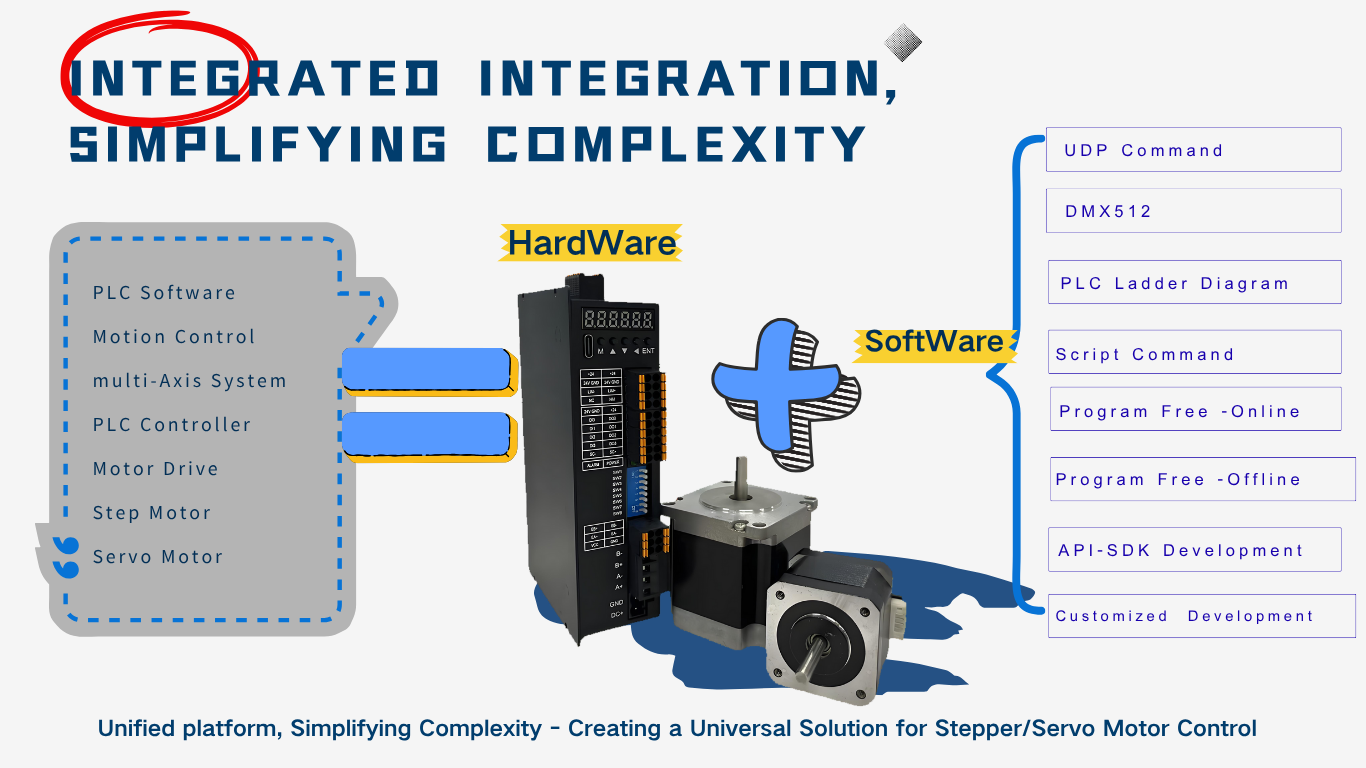

A Solution Provider Focusing On Software as Main Business, Integrating Motor Drivers and Motion Controllers as the Hardware Carrier.Reshaping Motion Control with SoftWare and HardWare: Complex Control, Simple Software Interface.

Technology Line

Refactoring motion control with software, complex control, simple interface

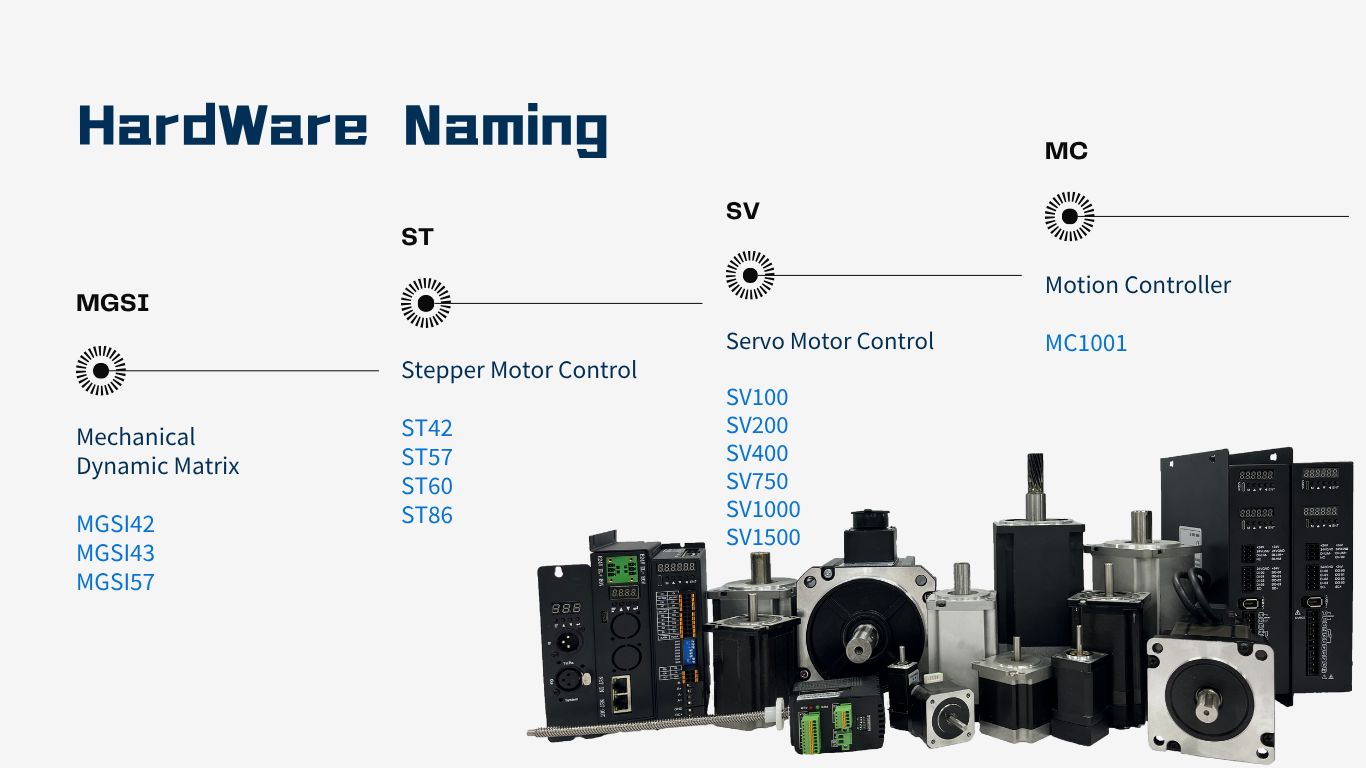

Focusing on integrated software and hardware solutions for stepper drive, servo drive, and motion control.

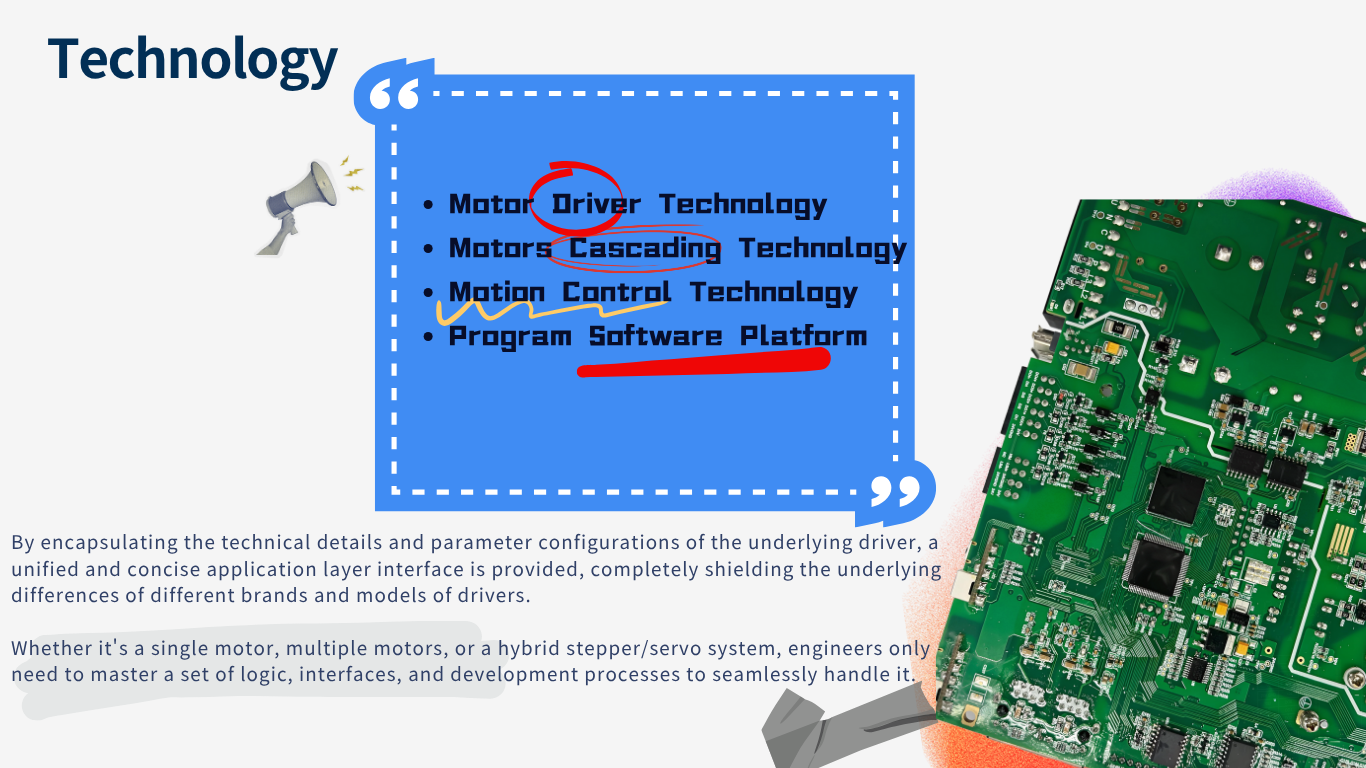

Focusing on servo motors, stepper motor drives, cascading, motion control, and software programming platforms, we provide a unified and concise application layer interface by encapsulating underlying technologies and parameters, completely shielding the underlying differences of different brand and model drivers. By mastering a set of logic, interfaces, and development processes, users can seamlessly handle single motor, multi motor, and stepper/servo hybrid systems, significantly reducing the threshold for cross industry applications.

Based on MStepper and MServo motor driver technology, we provide ready-made motion control drive controllers and customized solutions.

No PLC, no controller, no protocol learning, minimal wiring, no programming, weak programming, programmable, fast application, greatly reducing the threshold for debugging and application. And you only need to focus on the process parameters of your equipment.

Why do OEM Equipment Manufacturers Choose US?

Direct technical support

Equip each customer with dedicated professional engineers and provide free project support throughout the entire process

Innovative Technological Advantages

Drive control integration, integrated drive control, minimal wiring, compatible with the entire series of stepper servos, single axis multi axis arbitrary cascading

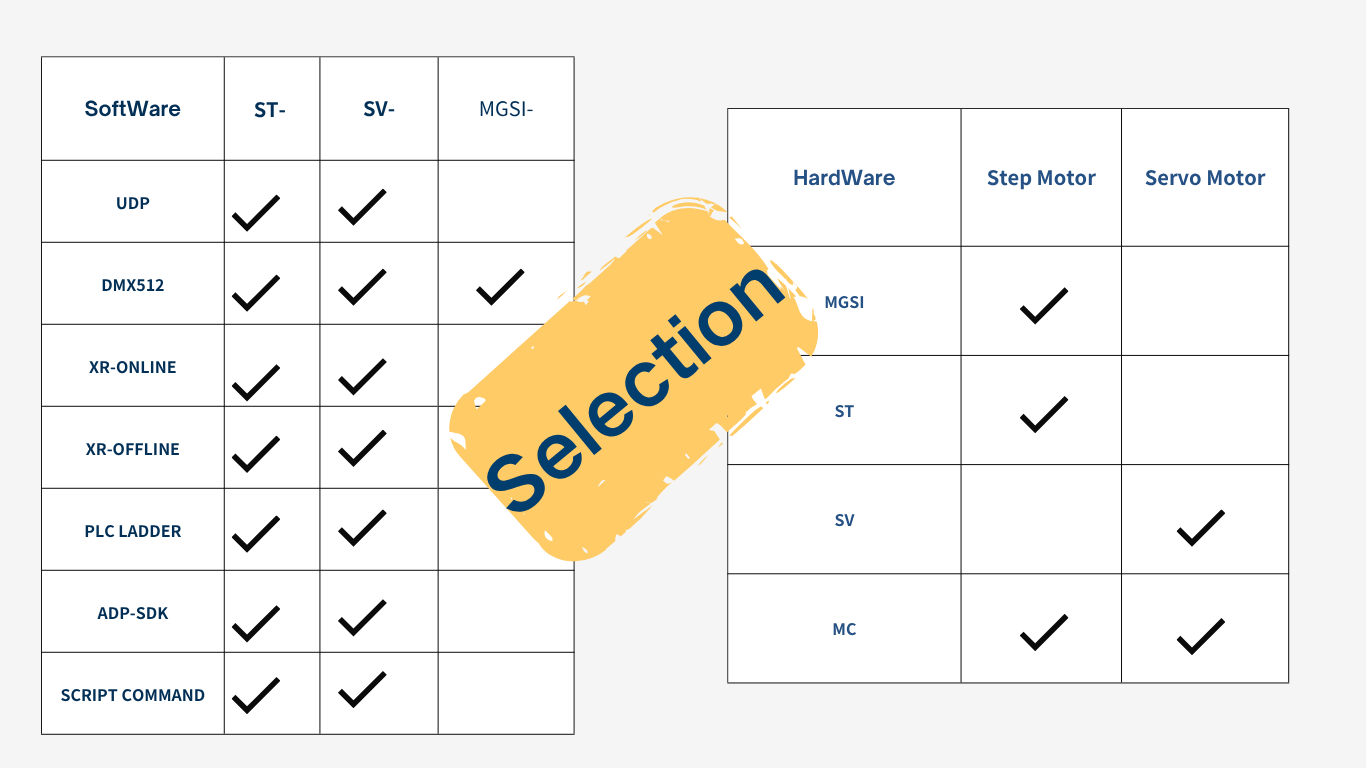

Only familiar once. Users only need to master a set of logic, interfaces, and development processes to seamlessly integrate the use of all MSP product stepper and servo series.

Quality and Reliability

All products are designed and produced in Shenzhen, and we adhere to independent control of the entire process from design to production. We adopt a lean single piece flow manufacturing mode in our core production base, coupled with a fully automated quality inspection system, to ensure that every equipment can withstand rigorous tests.

The ultimate pursuit of quality gives us confidence in providing sustained and stable performance for our entire product line, reducing customer maintenance costs in the later stages – we believe that reliable products are the foundation of cooperation.

Commercial Advantage

Create differentiated advantages from multiple dimensions such as selection, delivery, cost, full-service, software development, customized development, exclusive agreements, etc., and become your trusted long-term partner. This is incomparable to conventional automation parts suppliers or distributors.